A new Dh20 million 3D printing hub in Dubai is the latest step in transforming aviation into a more sustainable industry by producing lightweight replacement aircraft components.

The commercial airline industry has been a tough nut to crack as the world seeks solutions for more sustainable travel, with aviation contributing to up to 3 per cent of all global carbon emissions.

While electrified aviation remains in early development stages, the answer could lie in aircraft manufacturing processes and maintenance.

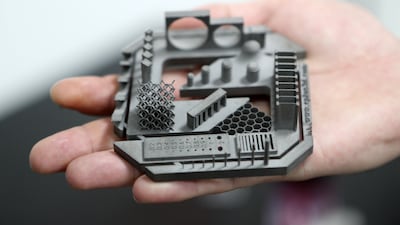

At the Paradigm 3D printing hub in Jebel Ali, lighter replacement parts can be created in just a few hours, reducing the need to import spares from Europe.

chief executive of AM Craft

Internal structures with components weighing up to 60 per cent less in replacement seating can also make a significant contribution to reducing the weight of aircraft, and fuel consumption.

Industrial 3D printers from Stratasys Ltd at the hub can print up to 2,000 parts a year, with plans to upscale production to 20,000 components over the next decade.

Helping airlines and the environment

“Having this capability in Dubai will reduce the lead time for replacement parts by weeks, possibly even months, helping airlines keep their planes in operation more predictably,” said Andreas Langfeld, Stratasys's president for Europe, Middle East and Africa.

“This will not only reduce operational costs, particularly around logistics, but it will also reduce the environmental impact associated with transportation of these spare parts.”

Around the world, leading aircraft and cabin interior product manufacturers including Boeing, Collins Aerospace, BAE Systems, Airbus, Diehl Aviation and Safran Seats, use additive manufacturing systems from Stratasys.

Paradigm 3D’s factory is currently the only service provider in the Middle East certified to produce 3D-printed parts for private and commercial aircraft.

Printed components include the seat trays, foot stools and arm rests found on most passenger airliners.

Home-grown

Producing spare parts in Dubai - one of the world’s busiest aviation hubs - should reduce the need for importing components that can be subject to delays in the global supply chain, the company said.

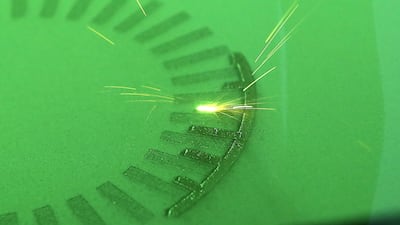

“When a commercial aircraft has a service call, usually there is a lot of labour involved,” said Scott Crump, who developed the Fused Deposition Modelling (FDM) used in the 3D printing process.

“There might be around 400 parts, including the rivets, that comprise a commercial airline seat.

“The consolidation of these is really important. A plan comes out of a certified digital library that typically the airlines have access to.

"Then you press a button on our machine and you basically get the part printed out.”

The plant is the first in the Middle East capable of producing parts in accordance with EASA Part 21G aerospace regulations, an international safety benchmark.

Typical components produced at the complex include aircraft interior components for lavatories, electronic cooling ducts, environment control systems, gaskets and air intake manifolds.

“When these aircraft come in for refurbishing every second counts, and every hour counts because that's downtime,” said Mr Crump.

“The real benefit is when you take a state-of-the-art but complicated type of assembly and you put it into a single production.”

Commercial airliners consist of thousands of individual parts that need to be certified and regulated for use, with a fully assembled Airbus A320 made up of about 340,000 separate components.

The 3D-printed materials adhere to the same safety regulations as traditional material used in building aircraft, and are just as strong.

“Airlines operate globally, and the Paradigm 3D facility will enable both regional and global aerospace companies to benefit from decentralised and on-demand manufacturing,” said Janis Jatnieks, chief executive of AM Craft, a company providing manufacturing services for airlines.

“This is a one-stop-shop for designing, manufacturing and post-processing certified aircraft components exactly when and where they are needed for immediate installation.”