Researchers who design parts for rocket ships are looking to help Abu Dhabi become a manufacturing-on-demand hub for major industries like aerospace and energy.

Three-dimensional printing was meant to revolutionise how we made things.

However, over three decades of development, it has not quite caught on — you didn't print your last pair of running shoes from a tabletop machine in your home.

While consumer-facing 3D printing, or additive printing, is likely to remain the stuff of science fiction for some time, its use in modern supply chains is now mainstream.

Technology Innovation Institute

"Most consumer products, sporting goods, automobiles and aeroplanes have benefited from additive manufacturing at some point in their design and production lifecycle," according to the Wohler's Report, a research publication that has been tracking the industry for the last 28 years.

For example, Boeing uses 3D-printed parts in commercial jet engines manufactured by GE. And if you've driven a Dodge Challenger Hellcat, you've used a 3D-printed rotor to brake.

The 3D printing process reduced the weight of the part by more than half and improved how it handled heat, making it a better performer than a traditionally made cast-iron piece, according to Wohler's.

In Abu Dhabi, a team of seven researchers is working to get a place at the table, which has long been dominated by the US, Germany, the UK and China.

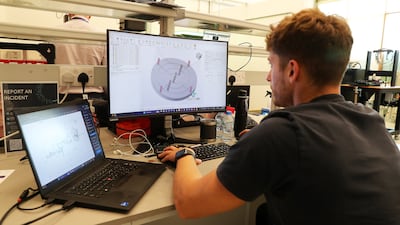

Their work at the additive manufacturing lab at the Technology Innovation Institute, a government-backed entity for applied research, is focused on identifying applications for the local market.

They are also expanding the available library of materials and metals used by 3D printers, identifying mixtures of metallic powders to create high-performing metals that are good heat conductors, strong and lighter weight.

Rocket parts

Down the hall from the additive manufacturing lab at TII is the propulsions and space research centre.

"They work on the design of rocket engines and the rocket parts, then they talk to us," Nesma Aboulkhair, head of the additive manufacturing lab, told The National.

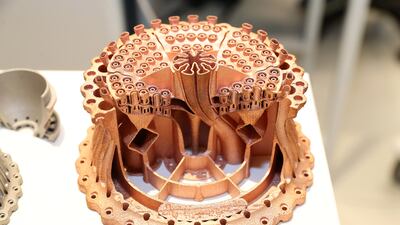

In traditional manufacturing, a rocket engine part may be three separate pieces, she said. But by using their 3D-printing machines and improving their ability to print using multiple materials, Ms Aboulkhair's team are developing a way to print the part as a single piece.

The machines they use are open-source platforms imported from Germany, equipped with sensors and monitors to capture data that helps the team develop better compounds.

"You can print the whole thing in one go ... no fasteners or screws," she said, adding that this capability changes the conversation.

"We push them [propulsions and space research centre] to design for performance, rather than design for manufacturing."

For now, their work is all prototyping, that is building a preliminary model for how something might be made in the future.

Print on demand

Over time, a commercialisation arm of the institute will work with its research labs to identify potential customers in aviation, aerospace, healthcare and energy to bring their best functional devices beyond the prototype to market.

"Let's say that BMW releases a new car, " she added, "they don't have to have spare parts for the next five to 10 years in stock to make sure that they covered the customers for the foreseeable future. All they need is to store a digital inventory of all the spare parts they need and print them on demand.

"That's the vision that we're going for, we want the factory of the future to be manufacturing-on-demand."

No tools are needed for this kind of manufacturing, things can be made one at a time and costs are fixed, making on-demand manufacturing a very competitive way to make things, according to Thierry Rayna, a professor at Ecole Polytechnique in Paris who studies additive manufacturing.

He predicts that once data collection and internet-enabled devices become more ubiquitous, 3D-printed objects "will thus cease to be a niche technology".

"It will then be possible to print a large number of objects ... for which customisation will be fine-tuned and automatic, with real added value," he added.

This capability will allow the UAE to become a more self-sufficient manufacturing hub.

"The manufacturing landscape in the UAE is relatively young comparatively," Ms Aboulkhair said.

She sees 3D printing as allowing the country to leapfrog others.

"We saw in the Covid-19 lockdown that if you didn't manufacture your own things, you were just stuck, because the whole world came to a stop," she added. "So you couldn't get any products or spare parts.

"Whereas the country that was a manufacturer was the one that was self-sufficient. And that's when governments started to realise how additive manufacturing can be empowering and a key enabler."

The institute's research lab dovetails with Abu Dhabi’s industrial strategy, a 10-year plan that aims to double the sector’s GDP contribution by 2031, increasing development in infrastructure, bringing down operational costs and improving regulations and access to financing.

The "Make it in the Emirates" campaign encourages local and international investors to manufacture and export products from the UAE.

Additive manufacturing still has hurdles in order to scale, such as a lack of global standards and the high start-up costs to enter the space.

It's also still time-consuming. At the institute, a small rocket engine prototype part about 13cm in height takes 24 hours to print.

But analysts say the pandemic reignited interest in on-demand manufacturing, and governments, including the UAE's, are doubling down on making progress.

"It's a complete paradigm shift," Ms Aboulkhair said, and her team are working to accelerate the change.