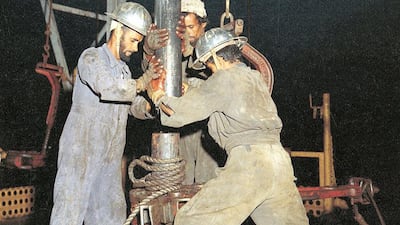

In five years, Abu Dhabi National Oil Company’s Drilling unit has generated $2 billion in cost savings for Adnoc, partly through adoption of digital technologies.

The use of state-of-the-art work processes, including advanced analytics, predictive maintenance techniques, and virtual reality training has vastly improved efficiency within exploration and production.

Using real-time technology to analyse big data streams, the company's well performance has improved consistently each year, by five to 10 per cent, since 2016.

Upstream Production

With a key focus on four main areas of operation, Adnoc Drilling has fully digitised its training practices, real-time monitoring techniques, maintenance prediction and drill cab operations.

Khalid Abdul Samad, senior vice president for Upstream Production, said drilling operations across its 96 rigs were "faster and more accurate", meaning they were less likely to end up with a dry well.

“Our real-time monitoring centre connects all of our rig sites to one central hub where we can read all our parameters,” he told The National.

“We are monitoring 49 KPIs, such as the speed of penetration of a drill and the downtime of a rig if it needs maintenance.

“From this data centre we can see that rig one, for instance, is doing great with connection time, so we make that the benchmark for the other rigs and send the data on to our different sites.

“We saved about 30 per cent in well duration since 2016, that’s $1 billion in total. To put that into context, whereas before it might have taken 100 days to drill a well, today it takes just 70.”

State-of-the-art training centre

In terms of training, Mr Samad said it takes a high school graduate about six months to qualify as an assistant driller at the company.

New staff are put through various stages of practical and theoretical training at the Drilling Training Centre, located in the Al Dhafra region of Abu Dhabi.

There are three different types of simulators located at DTC, alongside training programmes and mechanical and electrical workshops, to help students face real-life situations that they are likely to encounter at rigs.

A virtual reality system is used to give candidates a basic orientation about rig operations and rig equipment.

There are also three additional simulators, accredited by the International Well Control Forum, designed to reinforce and improve the candidate’s knowledge of “kick detection, shut-in procedures and well kill methods”.

Lastly, new staff undergo additional practical training in the “tubular-handling simulator”.

Here, new recruits learn how to trip in and out of a drill hole as well as learn how to make drill pipe connections using a power tong or a top drive, all within a virtual setting.

“In 2004 we established a small drilling school to develop Emiratis in drilling operations and in 2016 it was converted into the Drilling Training Centre,” said Mr Samad.

“More than 4,000 courses have been conducted at the site since 2016. It utilises the best in technology and trainees get to see dashboards and control systems as they would appear on the field.

“The main benefits of a digitised training centre is that candidates are less exposed to health and safety issues. Oil and gasfields are harsh environments, so this limits their exposure to toxic gases.

“Also, in simulators you can make mistakes, in real-time that is not an option without consequences.”

The digitised training approach saves a lot on logistics too, he said, in that there is no need to send trainees to different sites as everything is taught in one place.

Since 2016, more than 1,000 Emiratis who were trained at the centre have joined Adnoc’s drilling teams, working on the company’s onshore, offshore, and island rigs.

Maintenance prediction using AI

Artificial intelligence has become a huge part of operations at the Drilling unit and has been heavily utilised in maintenance prediction practices.

In early 2020, an AI pilot was launched at a number of offshore drilling sites that proved to increase efficiency and save Adnoc millions of dollars while advancing health and safety practices.

Mr Samad said the company’s AI system could "anticipate problems early enough to take corrective actions" and avoid hours or days of non-productive time due to tight holes or stuck pipes.

“When drilling, [imagine there is a certain problem I have], for example, a stuck pipe,” he said.

“There are different formations and zones in the ground so sometimes the pipes get stuck due to certain movements.

“How we predicted such problems before was by a human. They were measuring different parameters such as the speed of penetration of a drill or the amount of pressure when injecting mud into a well.

“Before, they could only predict an issue, like a pipe getting stuck, about two minutes before an incident occurred, that’s too late.

“With AI, it gives us ample time to predict a problem so we can interfere at the right time and execute the right intervention processes to prevent the pipe from getting stuck.”

The lead time today is about two hours, which is a fast improvement on two minutes, he said.

And in drilling, time is money. Having these sophisticated prediction tools in place, Mr Samad said, greatly reduced the downtime of any rig, meaning less risk of losing money.

Over the next few years, Mr Samad said Adnoc Drilling plans to accelerate the “deployment of digital technology” to significantly increase its production capacity by 2030.

From trainees to field workers

Khalid Abdel Karim started his training at the DTC and is now working in the field as an assistant driller in Abu Dhabi.

“It is amazing to sit in the simulator chair and see on the monitor real operations happening,” he said.

“The simulator helps operators across every level of the organisation, from entry level to senior engineers. Everything I learnt was just like being at a drilling site.”

“When Adnoc Drilling began, it was heavy, hard work on site. Now we are able to precisely and accurately move huge machinery with a joy stick. We practise doing that in the Training Centre so by the time we get to site we are ready.”

“I love my work because it is a way for me to return to my country what my country has given to me.”

Taha Al Hashmi is a drilling IDS engineer at the Bab oil field. In his role, he receives a digital live feed with up-to-date technical information as his team’s drilling occurs.

“Constant improvement is part of the culture of Adnoc Drilling,” he said.

“What is exciting here is our advanced combination of digital and physical drilling aspects.

“Digital real-time monitoring plays a crucial role in ensuring precision and excellence. Drilling is fundamental to the UAE’s growth. I am privileged to be part of it.”

____________________